CABIN-SAFE™ Ultrasonic Leak Detecting System

WHAT IS CABIN-SAFE™?

The CABIN-SAFE™ is perfect for detecting the source of any leaks in any small enclosures, fuel tanks leisure craft, yachts, cars and caravans.

The CABIN-SAFE™ is a lightweight ultrasonic system used to detect holes. The complete system is contained in one carry case for convenient transportation. With a complete weight of only 550g, including the batteries, the CABIN-SAFE™ is able to be carried onto an aircraft as hand luggage. It is also incredibly simple to use and requires no training to operate.

To use the CABIN-SAFE™ the transmitter unit is placed inside the vessel and the Sonic Leak Detector (SLD) is used to inspect seals, doors and windows on the outside for finding holes or places of potential water ingress. Ultrasound will be detected on the exterior if a hole is present in the structure or seals. Any holes may lead to water ingress.

Step by step guide to using the CABIN-SAFE™ for hole detection –

- The CABIN-SAFE™ transmitter is placed inside the container, vessel or vehicle. The magnetic base can be used to hold the transmitter in a convenient place. The unit should be switched on, and the green LED should flash.

- The headphones are plugged into the SLD receiver. The trigger turns on the SLD (Sonic Leak Detector) and the laser will shine out of the tube. The tube is often referred to as the nose. It is there to direct the sound into the internal microphone.

- The surveyor begins to inspect the vessel or vehicle, moving the SLD across the exterior of the vessel. Any gaps through which air or water can pass will allow the ultrasonic signal to pass and can be detected.

- Any ultrasound that can escape to the outside is converted to an audible sound that can be heard through the headphones. The louder the sound, the larger the leak.

Step by step guide to using the CABIN-SAFE™ for gas detection –

The SLD (Sonic Leak Detector) when used on its own allows the rapid detection of pressurised gases escaping from any form of plant system.

The ultrasound ‘noise’ generated from any gas, e.g. – compressed air, steam, refrigerant or vacuum, bad bearings and electrical arcing can be easily detected, and the leak location can be rapidly and accurately identified through the headphones.

The SLD can significantly reduce leak detection times and produce substantial cost savings.

Savings potential in compressed air plants –

In many companies, compressed air systems have leaks in the ducts, coupling and hoses (leakages of 30% and more are not uncommon).

This results in significant costs for the company. Moreover, this results in additional unnecessary maintenance measures are required for the compressor and the compressed air processing.

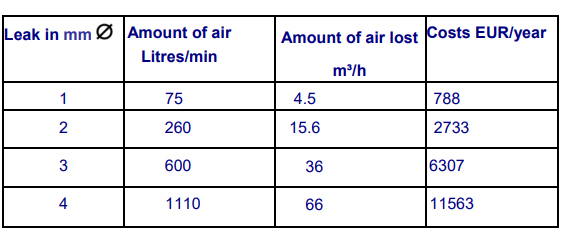

The following example clearly shows the financial consequences of smaller leaks, (which are acoustically hardly perceivable by the human ear). Average operating costs for compressed air costing 0.02EUR/m³ at 7 bar; per year, see chart below –

- The CABIN-SAFE™ transmitter unit

- Sonic leak detector (SLD)

- Foam-lined black polymer case

- Hard hat compatible headphones

- 4 batteries

- Full operating instructions

- 3-year warranty

- 4 batteries

The CABIN-SAFE™ is used to test the weather tightness of :

- Yacht Cabins

- Windows

- Caravans

- Hatches

- Cars

The CABIN-SAFE™ can check for holes in:

- Ship Containers

- Fuel Tanks

- Refrigeration Units

- Double Glazing

- It can locate holes with pinpoint accuracy

- It causes no damage to the interior of the vessel or vehicle

- It can be conducted and used in sub-zero temperatures

- It does not interfere with other crew activities

- It does not compromise the safety of the crew

Entire CABIN-SAFE™ unit –

- Operational Weight – 400g

- Shipping Weight – 550g

Transmitter –

- Weight – 190g

- Dimensions – 110 x 70 x 34mm

- Power supply: 1 x 9v PP3 – 40 hours of battery life

- Operation: ON/OFF Switch and LED indicating low battery

- 3-year warranty

Sonic Leak Detector (SLD)-

- Weight – 140g

- Dimensions – 190mm x 90mm x 60mm

- Power supply: 9v PP3v disposable or rechargeable batteries

- Low battery warning is indicated by the laser flashing on and off *

- Simple controls – ON/OFF push button and headphone volume control

- Frequency Range – 20KHz – 200KHz

- 3-year warranty

*Once the low battery warning has begun, results taken after that should be discredited and you should not resume use until the batteries have been replaced.

Microphone –

- Broadband Electret Microphone

Headphones –

- Weight – 50g

- 5mm stereo jack plug 9 can be used for stereo or mono headphones)

- Hard hat compatible

- Warranty – 6 months

ISO 9001:2015

NATO Stock Number 6635-99-883-3612

NCAGE Number U0B22

IIMS Corporate Membership Number C508

International Customer Base and Exceptional Service.

Accreditations and Affiliations

ABS Type Approved Equipment

Get a Quick Quote

World Leading Designers and Manufacturers

We are proud to be British based designers and manufacturers of world-leading ultrasonic water integrity testers, liquid level indicators and non – destructive test equipment.