WHAT WE DO

Water Ingress Detection

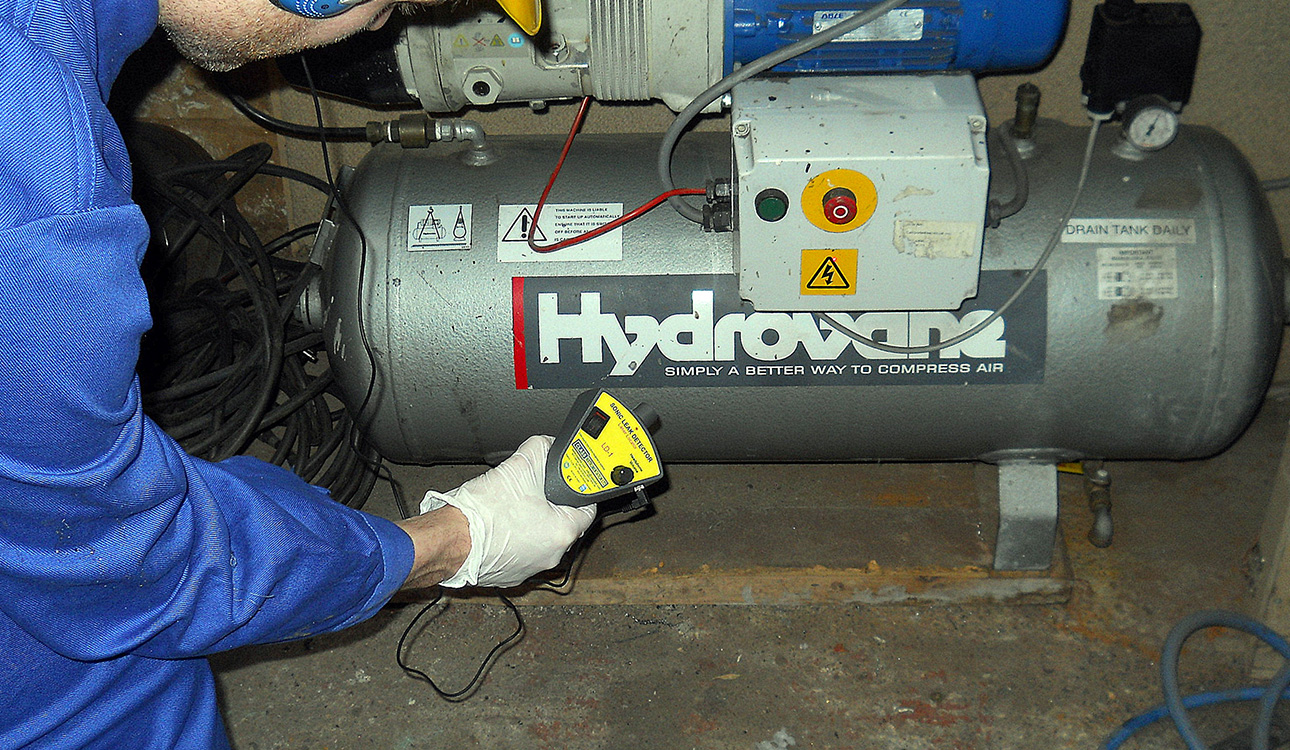

Where ever there is the need to stop water ingress there is a good chance that ultrasonic can help.

Often called ‘UT’ or ‘UT testing’ it consist of generating ultrasonic sound using an ultrasonic transmitter, placing this physically on one side of whatever you are testing and then checking on the other side with a receiver tuned to the transmitter frequency to see if there is any ultrasound detected. ultrasound can only be heard an air hole.

Ultrasound is not audible so the receiver converts the ultrasound to an audible sound.

This audible sound is heard through headphones or a small internal loudspeaker. If it is desirable to know the size of the hole, then we have products that will display the intensity in decibels. Decibels are the universal unit for sound measurement.

The product we make to test for leaks in hatch covers and atriums where there is a large volume that needs testing we suggest our Cargo-Safe.

Cargo-Safe hatch-cover testers are used globally by marine surveyors and fleet owners. We have pioneered manufacturing of these for 24years and have set the world-wide standards for their use, DNV TAP403.

Atriums and buildings in general need to be sealed against the rain and using our Cargo-Safe is the best products for checking for holes as covered in EU DIN EN 12599, DIN EN 14134, DIN EN 13779. If it is on a smaller scale like water-tight and weather-tight doors, we suggest our Door-Safe.

If it is on a small scale and is a low budget like testing trams and trains, then our Cabin-Safe System is recommended.

FIRST CLASS PRODUCTS

Ultrasonic Testing Equipment

CARGO-SAFE™

Ultrasonic Hatch Cover Tester

The choice of marine surveyors across the globe. The ingress of water through leaking hatch covers is a main cause of damage to cargo. It is in the interest of ship owners, managers and insurers to guarantee the cargo hold is watertight, as damaged cargo caused by water leaking through hatch covers…

CARGO-SAFE DATA™

Ultrasonic Hatch Cover Tester

The CARGO-SAFE DATA™ is a lightweight ultrasonic system for testing weather – tightness of cargo hatch covers. The CARGO-SAFE DATA™ allows for rapid and thorough testing of weather – tightness of cargo holds, as well as the bow, the side and stern doors, and any openings that need to be sealed.

CABIN-SAFE™

Ultrasonic Leak Detecting System

A smaller, less powerful version of Class Instrumentation Ltd’s CARGO-SAFE™ unit, this boat survey product is perfect for detecting the source of leaks in small pleasure craft, yachts, cars and caravans. To use the Cabin-Safe, the Transmitter unit is placed inside the vessel …

DOOR-SAFE™

Water-Tight Tester

The fully ABS Type Approved Door-Safe™ ultrasonic kit is used to rapidly and accurately test the integrity of water-tight doors and hatches.The Door-Safe™ WT tester kit consists of 2 units, an ultrasonic transmitter unit and a portable, hand-held receiver unit connected to a …