CARGO-SAFE DATA™ Ultrasonic Hatch Cover Tester

WHAT IS CARGO-SAFE DATA™?

CARGO-SAFE DATA has marked us out as the leading provider for sophisticated leak detection. The CARGO-SAFE DATA enabled leaks to be found in a large range of situations from cable transits, weather-tight and water-tight doors, hatches, stern and bow doors up to full size hatch covers for cargo ships. Ultrasonic testing completely replaces chalk or hose testing and replaces it with an environmentally friendly non-polluting fast and accurate digital alternative.

The ABS Approved CARGO-SAFE DATA is the combination of a Cargo-Safe and Door-Safe with the added ability to store data on a memory stick for down loading onto a computer or smartphone. This feature rich product will perform without compromise hatch-cover testing for the largest of ships and water-tight, weather-tight doors and transit testing.

How the CARGO-SAFE DATA™ works

The CARGO-SAFE™ works in a very simple way. After the hatch covers are closed, the transmitter generating an ultrasonic signal is placed in the cargo hold, which then emit ultrasonic waves(the cargo hold can be empty or loaded with cargo).

The surveyor or operator then uses the CARGO-SAFE™ ultrasonic receiver to ‘listen’ from outside of the hold and detect any ultrasonic sounds that pass through any holes in the hatch cover with pinpoint accuracy. The size of the leak can be established by the strength of the signal detected.

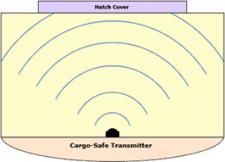

The CARGO-SAFE™ hatch cover leak detection system has three levels of emitters: upper, lower and vertical. This means that ALL of the ultrasound is directed to the hatch covers, optimising its effectiveness.

The diagram shows the dispersion pattern of the ultrasonic sound emanating from the CARGO-SAFE DATA™ transmitter.

The CARGO-SAFE DATA™ has a high sound pressure level, so it is ample enough to fill even the largest of holds, to enable reliable and accurate readings.

- The CARGO-SAFE DATA™ transmitter is placed in the cargo hold.

- On the deck, with all the hatches closed, the microphone and headphones are plugged into the receiver.

- The surveyor begins to inspect the hatch, holding the microphone against the hatch seals. Any gaps that either air or water could pass through will also allow the ultrasonic signal to pass through – and be detected.

- The display on the receiver shows the decibel level of any ultrasound leaking through the hatch seals. The signal can also be heard through the headphones.

- The flexible microphone and the extension arm allow the position of any potential leaks to be identified with pinpoint accuracy. The size of the problem is established by the strength of the signal detected.

- Carry Case

- A receiver in a leather case with a waist and neck strap for hands-free use

- Transmitter in a leather case with neck strap for hands-free use

- 2 yellow microphones

- Extension arm with wrist strap

- Emitter tester (for pre-survey checks)

- Emergency microphone lead

- AA rechargeable batteries (6 in the transmitter, 4 for the receiver, and 10 spares)

- Battery charger

- DC lead for external use (if the AA batteries are flat)

- Hard hat compatible headphones

- 5mm headphone splitter – so two people can listen at once

- Operation manual – both A4 paper and memory stick

- Yellow hi-vis vest

- P&I approved inspection sheets

- Class Instrumentation pen

- Chalk to mark areas of leaks

- Memory stick with operational manual and training video

- Micro USB to standard USB lead

CARGO-SAFE DATA™ can be used to test the tightness and water integrity of:

- Cargo hatch covers

- Bow and stern doors

- Access hatch seals

- Watertight doors

- Weathertight doors

The CARGO-SAFE DATA™ was designed for use within the Indian Navy, making it operational even in high heat and humidity.

Unlike hose testing, ultrasonic testing has many benefits and no drawbacks.

- It is compliant with port and harbour environment management plans

- It does not pollute the marine environment

- It can locate holes and tears in hatch seals with pinpoint accuracy

- It causes no damage to cargo

- It can be conducted in sub-zero temperatures

- It can be carried out with the cargo in place

- It does not interfere with the other crew activities

The CARGO-SAFE DATA™ is sold with a device that can be used to check the emitters, the inspection microphones, the extension arm and the microphone emergency lead (The EMEA Tester). It is recommended that this is complete between each survey to ensure accurate results.

The CARGO-SAFE DATA™ hatch leak detector is calibrated at the factory and we predict it will stay calibrated for 5 years.

The constant output circuitry guarantees that the ultrasonic output of the transmitter is constant throughout the entire battery life. You can see this by the green flashing LED’s.

- Shipping Weight: 4Kg (8.8lbs)

- Operational Weight: 1.5Kg (3.3lbs)

Transmitter –

- Weight – 475g

- Dimensions – 190 x 100 x 60mm

- Output – 157dB @ 40 khZ

- Power supply – 6 x AA rechargeable or alkaline batteries

- Battery life – 5 – 6 hours

- Environmental protection – with leather case closed = IP66 (IEC529 + IEC144)

– with end flap opened = IP40 (IEC529 + IEC144)

- Fastenings – neck strap for hands free use

– anchor points to suspend the transmitter if there is no surface available

- Temperature range – -20°C to +60°C (high humidity durability)

- Warranty – 3 years

Receiver –

- Weight – 350g (12.3oz)

- Dimensions – 160 x 100 x 30mm (6.3” x 3.9” x 1.2”)

- Power supply – 1 x 9v PP3 rechargeable or alkaline battery with 40 hours nominal usage

- Switchable between dB and percentage of Open Hatch Value (OHV)

- Can be used with headphones, or an internal loudspeaker can be used instead

- Can be used with a microphone, or internal microphone in the event of mic loss

- Weather-resistant leather case – IP66, designed to protect if dropped

- MAX HOLD capability to record maximum readings

- Backlight button with ON/OFF or automatic OFF after 30 seconds for battery saving when not in use

- Radio control button to switch from ON/Standby/OFF etc

- Warranty – 3 years

Microphone –

- Weight – 110g

- Dimensions – 330 x 10 x 10mm

- Fastenings – BNC connection to extensions arm or emergency lead

- Temperature range – -20°C to +60°C (high humidity durability)

- Warranty – 6 Months

Headphones –

- Weight – 50g (1.7oz)

- 5mm stereo jack plug

- Hard hat compatible

Emitter –

- Weight – 17g (0.6oz)

- Dimensions – 46 x 31 x 20mm (1.8″ x 1.2″ x 0.8″)

Extension Arm –

- Weight – 150g (5.3oz

- Dimensions – 390 x 40 x 30 mm (15.4” x 1.8” x 1.2”)

- Dimensions when extended: 1150 x 40 x 30mm (45.3″ x 1.8″ x 1.2″)

- Wrist strap for hands free use

- Extends to 1150mm

- Warranty – 6 months

Spare Microphone and Emergency Lead –

- To be used in the event of either microphone or extension arm loss

Battery Charger and Batteries

- 20x rechargeable AA batteries (for transmitter)

- 2x PP3 9v batteries (for receiver)

- Global battery charger with car adapter

Emergency Power Lead

- For emergency power to the transmitter in the instance of a failed battery

- Can accept an external power supply of 9 to 24 volts DC

ABS Manufacturing Assessment

Download A Brochure

ISO 9001:2015

IIMS Corporate Membership Number C508

The Nautical Institute Corporate Membership Number CA00059

NCAGE Number U0B22

NATO Stock Number 6635-99-958-4633

CE Mark BS EN 60945:2002

International Customer Base and Exceptional Service.

Accreditations and Affiliations

ABS Type Approved Equipment

Get a Quick Quote

World Leading Designers and Manufacturers

We are proud to be British based designers and manufacturers of world-leading ultrasonic water integrity testers, liquid level indicators and non – destructive test equipment.