WAS WIR TUN

Programmierte Wartung

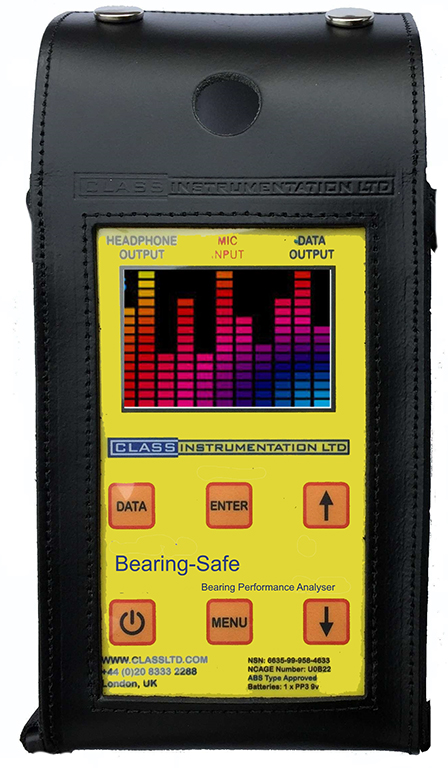

Überwachung Übermäßige Vibrationen in rotierenden Maschinen sind der Schlüssel zur Früherkennung möglicher Anlagenprobleme. Bei der Vibrationsüberwachung werden Beschleunigungsmesser verwendet, um Änderungen der Amplitude, Frequenz und Intensität von Kräften zu messen, die rotierende Geräte beschädigen. Die Untersuchung von Vibrationsmessungen ermöglicht die Entdeckung von Unwucht, Lockerheit, Fehlausrichtung oder Lagerverschleiß in Geräten vor einem Ausfall. Eine regelmäßige Überwachung kann zukünftige Ausfälle vorhersagen und kostspielige Ausfallzeiten vermeiden. Lange bevor ein Lager ausfällt, erzeugt es Geräusche in der einen oder anderen Form. Der Frequenzbereich reicht von physischem Schütteln bis hin zu sehr hohen hörbaren Tönen. Die Lautstärke (Amplitude) kann anfangs sehr klein sein, was bedeutet, dass Sie sie nicht bemerken (insbesondere in einer lauten Umgebung), es sei denn, dieser Ton kann verstärkt werden. Unser Lagersicher nimmt das Geräusch mit seinem Sensor auf, analysiert es und zeigt die Art von Problemen grafisch an, damit ein Wartungsplan oder eine Reparatur durchgeführt werden kann, wodurch die Reparatur problematischer Komponenten vor dem Ausfall ermöglicht wird. Die Zustandsüberwachung hilft dem Anlagenpersonal nicht nur, die Wahrscheinlichkeit eines katastrophalen Ausfalls zu verringern, sondern ermöglicht es ihm auch, Teile im Voraus zu bestellen, Arbeitskräfte einzuplanen und andere Reparaturen während der Ausfallzeit zu planen. Dadurch können erhebliche Kosten gespart und unvorhergesehene Ausfälle vermieden werden.

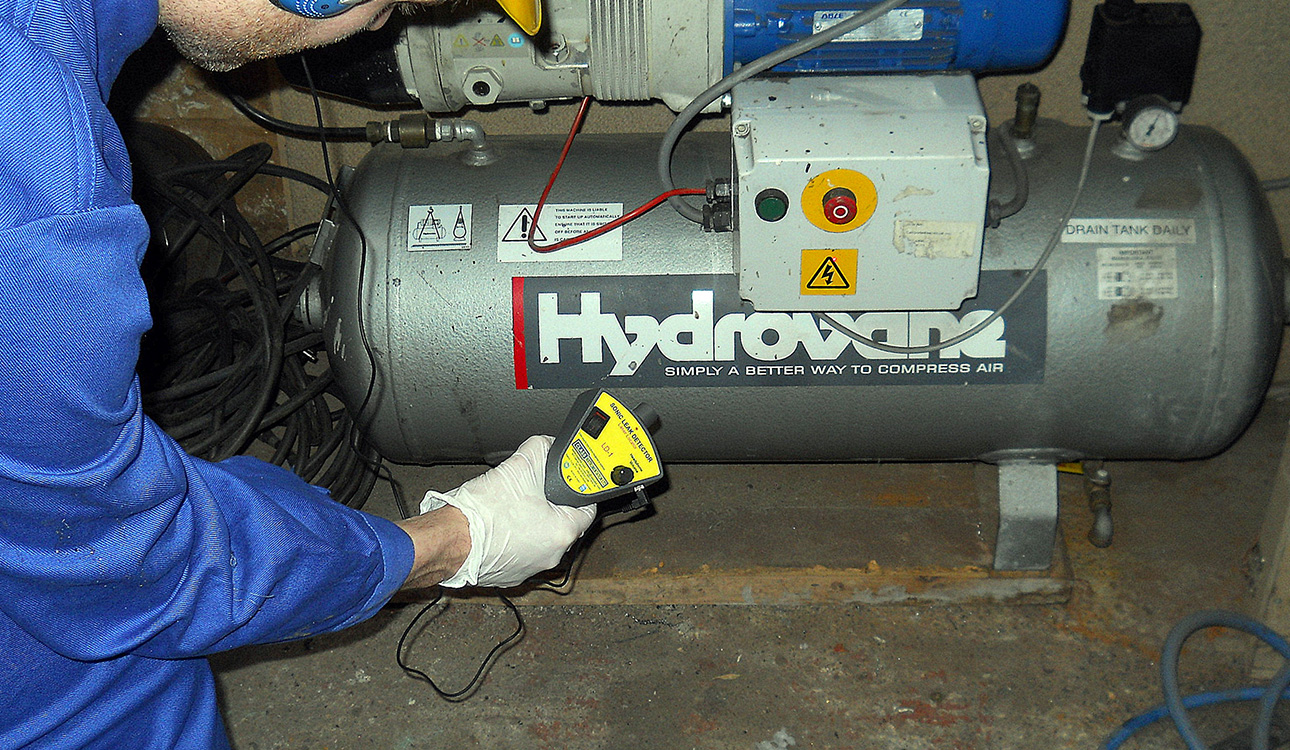

Überwachung und die Erkennung von Gaslecks oder Luftlecks kann Sie auf versteckte Geldverschwendungsfehler aufmerksam machen. Die von solchen Lecks abgegebenen Frequenzen sind normalerweise Ultraschall, sodass ein Breitband-Ultraschallempfänger benötigt wird. Darüber hinaus wird Ultraschall auch durch Koronaentladungen an Hochspannungsgeräten vor einem katastrophalen Zusammenbruch abgegeben. Unser SLD ( Schalllecksucher ) ist das Produkt für diese Anwendung.

ERSTKLASSIGE PRODUKTE

Ultraschallprüfgeräte

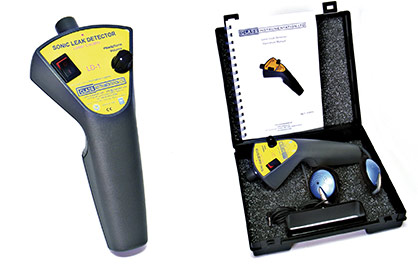

Schalllecksucher

Schnelle Erkennung von austretenden Druckgasen

Der Class Instrumentation Sonic Leak Detector ist ein kostengünstiges Instrument, das die schnelle Erkennung von unter Druck stehenden Gasen ermöglicht, die aus jeder Art von Anlagensystem entweichen. Das von einem Leck erzeugte Ultraschall-„Rauschen“ kann leicht …